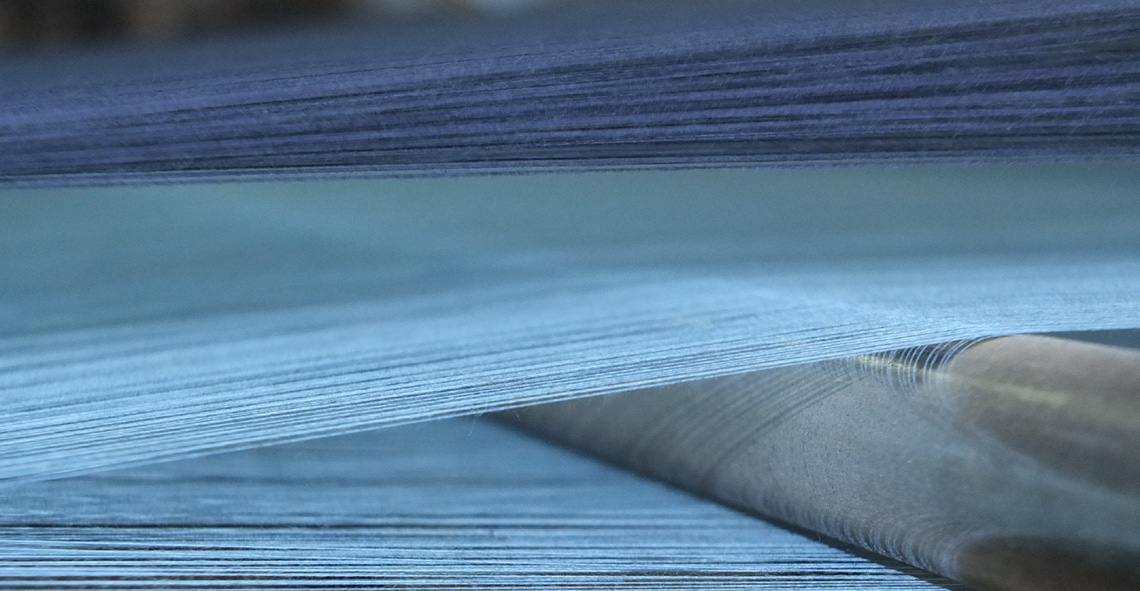

EKAGUM R: The Sizing Compound for all Fiber Types

EKAGUM R forms high-tenacity, elastic, and flexible sizing films which are adhering excellently to the sized yarns. Yarns sized with EKAGUM R are very soft and smooth, creating fabrics with a nice and even appearance. When sized with EKAGUM R even fine warp yarns or densely woven fabrics can be easily woven. Warps which were sized with EKAGUM R can be also processed on high performance weaving looms. EKAGUM R is a versatile, powdery, biodegradable product which can be applied on yarns of all kind of fibers. The compound contains a sophisticated combination of different polymers, polyvinyl alcohol and polysaccharides. It is mainly used as a single product. An additional sizing wax is only required, when particularly supple and soft threads are wanted. Depending on the processing temperature, we suggest the addition of EKAWAX 530 or EKAFIN 2 P. In general, a complete overwaxing of the warp on a separate overwaxing device is not necessary.

Advantages of EKAGUM R in Sizing and Weaving

Being a compound EKAGUM R offers clear advantages in the preparation of the sizing liquors, such as simple recipes, easy handling and low viscosity variation. Furthermore, EKAGUM R features a high stability against water hardness and mechanical action. An economic plus of EKAGUM R is the simple adjustment of residual sizing solutions to new concentrations, so that old liquors do not have to be discarded.

One of the economic and ecologic advantages of EKAGUM R is the comparatively low application temperature of below 60 °C needed in the size box. The sizing liquor shows optimal flowing properties and a quite low viscosity at these processing temperatures. Thus, yarn breakages in the size box can be significantly reduced. Due to the soft and smooth surface of the sized warp threads, the yarn/yarn and the yarn/metal friction as well as the clinging tendency are minimized. As a result, there are less machine downtimes at the sizing machine and the weaving looms. The good film formation also entails no or only little fiber fly, which significantly reduces the dust pollution in the weave room. Another economic advantage is, that the humidity in the weave room can be kept quite low when weaving warps sized with EKAGUM R. These warps show ideal running properties at a relative humidity of 55 – 65 %.

Advantages of EKAGUM R in Textile Finishing

It is sufficient to simply wash woven fabrics sized with EKAGUM R before dyeing and finishing. Due to its high acid and alkali stability the product does not tend to precipitate and can also be directly washed off in the alkaline bath. An enzymatic desizing is not required. The pretreatment processes can be implemented in a way that for example sized greige cotton fabric can be directly bleached, scoured or mercerized without a separate previous washing step.

Please Contact Us

Do you have questions on EKAGUM R? Further information about our sizing compound EKAGUM R can be found in our detailed product brochure. Just send us a message via our contact form.

- Friedrich Wullner

- Head of Sizing Department

- +49 175 2731494

- friedrich.wullner@drpetry.de